- table of contents

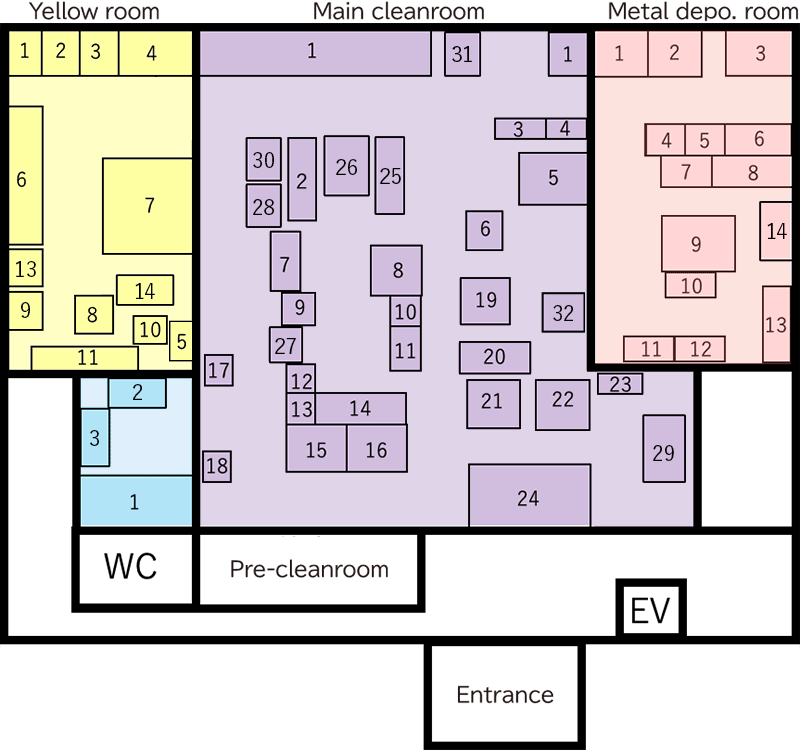

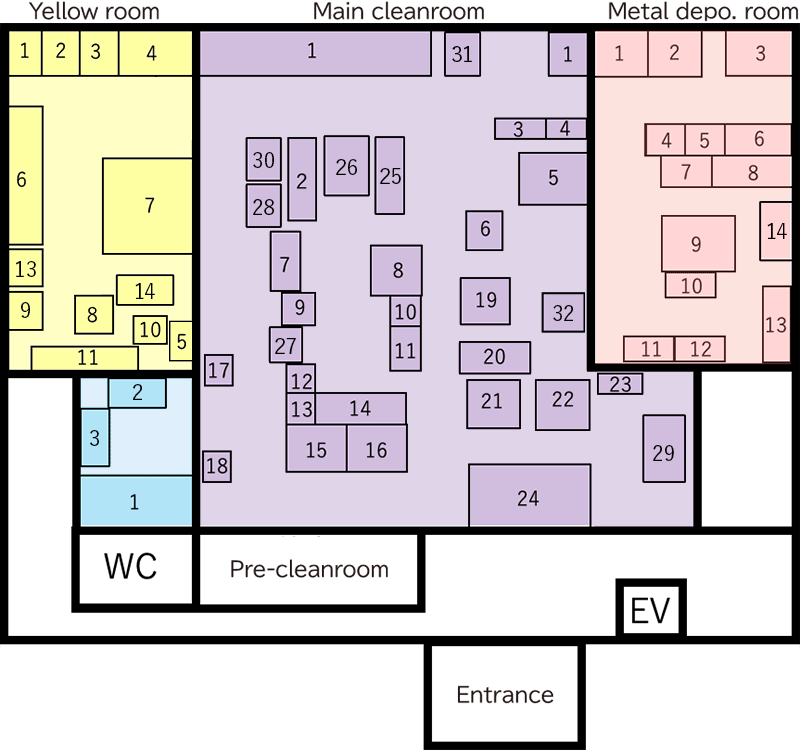

1F Cleanroom

You can check the corresponding device by clicking the number in the image.

Yellow room

- 1 EVG mask aligner

- 2 Megasonic Cleaner

- 3 EVG Plasma Activator

- 4 Fume hood

- 5 Two-fluid cleaner

- 6 Spin Coater、Oven

- 7 Laser Lithography System #1

- 8 Mask aligner#1(SUSS, MA6/BA6)

- 9 Mask aligner (SUSS) #2

- 10 HDMS treatment system

- 11 Spin Coater

- 13 Spray coater

- 14 Mask aligner#3(SUSS, MA8/BA8)

Main cleanroom

- 1 Fume hood

- 2 Thermal oxidation furnace

- 3 UV exposure

- 4 4-probe resistivity meter

- 5 ICP-RIE#3(Pegasus, MPX)

- 6 Asher for general use

- 7 Plasma/ozone TEOS CVD

- 8 Plasme TEOS CVD

- 9 ICP-RIE#1(MUC21)

- 10 Ellipsometer(UVISEL)

- 11 Plasma-enhanced SiN CVD

- 12 SiN etcher

- 13 SiCN Cat-CVD

- 14 CCP-RIE #3

- 15 CCP-RIE #2

- 16 Dual frequency RIE

- 17 EVG wafer bonder(EV520)

- 18 Supercritical CO2 drier

- 19 ICP-RIE#2(MUC-21)

- 20 CCP-RIE #1

- 21 FAB

- 22 Ion beam milling

- 23 Surface profilometer

- 24 Ion implantation

- 25 Wafer Bonder (EVG540)

- 26 Wafer Aligner (EVG SmartView NT)

- 27 Plasma cleaner (AQ-500T)

- 28 Plasma cleaner (ONTOS)

- 29 Flip chip bonder(FC3000W)

- 30 Excimer exposure

- 31 Lift-off EQP(LOB8)

- 32 Anodic bonding

Dark room

Metal deposition room

- 1 High-temp RF magnetron sputter(SSP3000)

- 2 DC sputter

- 3 RF magnetron sputter(ANELVA#2,SPC-350UHV)

- 4 Facing target RF sputter

- 5 EB evaporation

- 6 ECR ion beam sputter(EIS-220)

- 7 RF magnetron sputter(ANELVA#1,SPC-350)

- 8 Facing target DC sputter

- 9 Wafer bonder (Technofine)

- 10 RF magnetron sputter(Shibaura#2,CFS-4ES)

- 11 ECR sputter

- 12 RF magnetron sputter(Shibaura#1,CFS-4ES)

- 13 Fume hood

- 14 AlN Sputtering#1

Tohoku University

Tohoku University