Microwave nondestructive testing

Page 1 : Microwave NDT

Page 2 : Experimental set-up

Background of this research

Detection of defect in complex piping systems in early stage of degradation

with a high-speed and high-accuracy inspection method is serious concerns in the

operation of nuclear power plants.

The typical methods for detecting defects such as eddy current testing (ECT) and

ultrasonic testing (UT) are time/cost consuming because they need point-by-point

inspection for the long pipes.

Therefore it is desirable to develop another high-speed technique for crack detection.

One of the most promising techniques which might reduce the time/cost of the long range

inspection is the nondestructive testing (NDT) method using microwave.

We are investigating the microwave NDT to achieve high-speed inspection.

Microwave NDT

Microwave can be propagated through pipes rapidly.

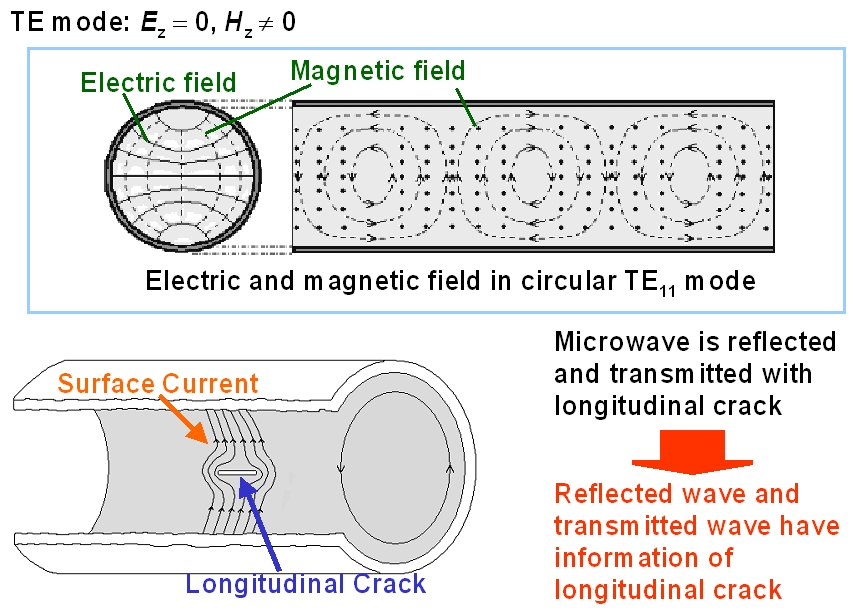

We can use TE-modes for detection of defect having longitudinal component,

a longitudinal crack for example.

The TE-modes are characterized by fields with Ez = 0 and

Hz ≠ 0, where z indicates

the direction of the axial direction.

When microwave wave of TE-modes is propagated in the pipe, the electric surface current

with a circumferential component is produced in the inner surface of the pipe.

Once this surface current flows in the pipe with a longitudinal crack, the crack prevents

the surface current from flowing.

Consequently some parts of the incident wave are reflected, which have information about

the crack.

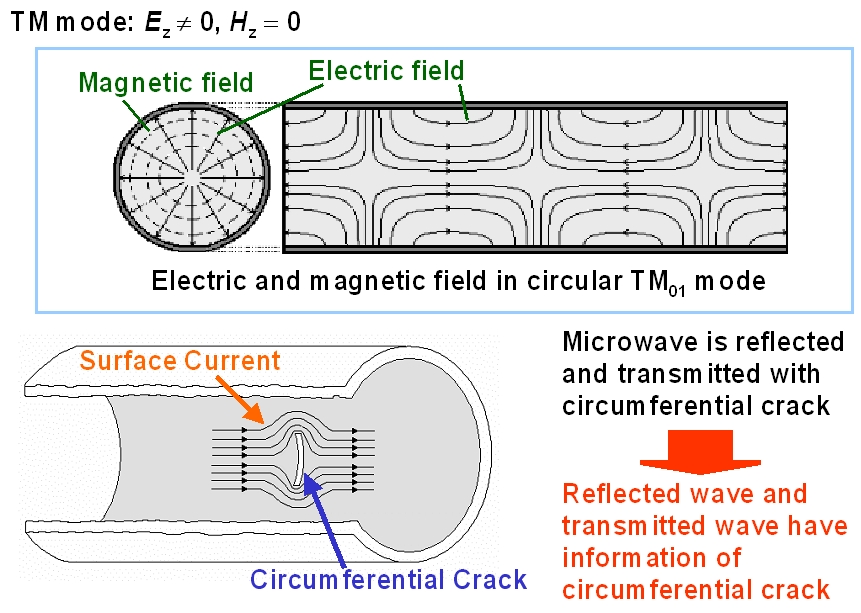

We can also use TM-modes for detection of defect having circumferential component,

a circumferential crack for example.

The TM-modes are characterized by fields with Ez ≠ 0 and

Hz = 0.

When microwave wave of TM-modes is propagated in the pipe, the electric surface current

with a axial component is produced in the inner surface of the pipe.

Then we can obtain information about a circumferential crack.

|

| TE mode |

|

| TM mode |

hashizume-stafflovehashizume@grp.tohoku.ac.jp

Copyright © Hashizume & Ito & Ebara & Cheng Lab., All Rights Reserved.