Flow-accelerated corrosion

Page 1 : Flow-accelerated corrosion

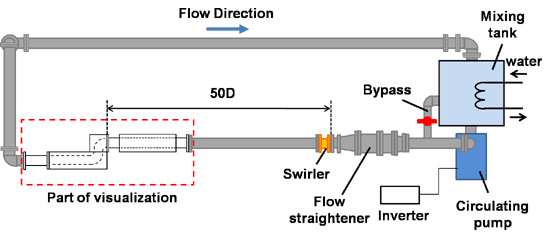

Page 2 : Experimental loop and visualization of flow structure

Page 3 : Investigation of Influence of Inlet Flow Conditions

on Flow Structure in a Dual Elbow

the inlet flow condition for a dual elbow is considered to be very complex in the actual plant.

So, it's necessary to evaluate flow structure under this complex flow condition.

Therefore, as the one of the methods to evaluate the influence of inlet flow conditions on flow structure in a dual elbow, a visualization experiment is being conducted using biased or swirling flows, which are forced to form as alternative inlet flow conditions into the fully-developed turbulence.

Biased Flow

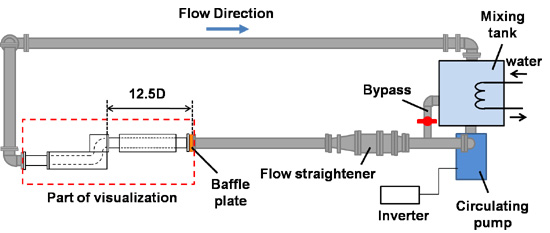

When the inlet flow condition is set to a biased flow, a baffle plate is embedded immediately upstream of the entrance section.

Its outer diameter, inner diameter, and thickness are 130, 56, and 3mm, respectively.

half of its flow path is occluded by a semicircular plate with 16 holes with diameter of 6 mm.

Also, the visualization experiment is conducted by changing the angle of the baffle plate.

|

| Baffle plate |

|

| Experimental loop (Biased flow) |

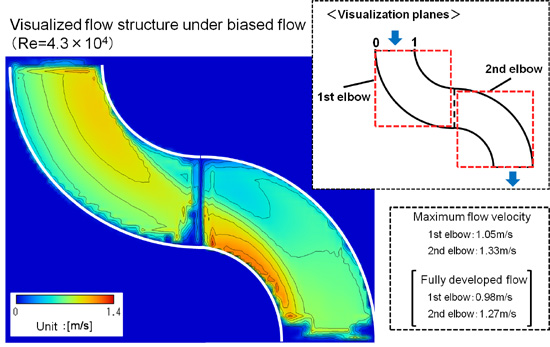

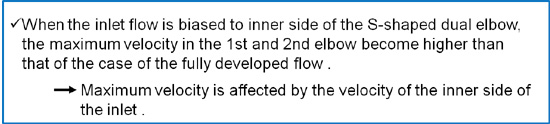

Visualized flow structure under biased flow

|

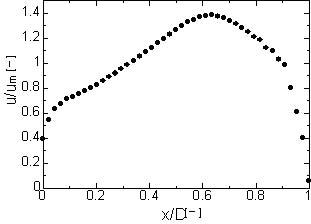

| Flow distribution at the inlet of dual elbow |

|

|

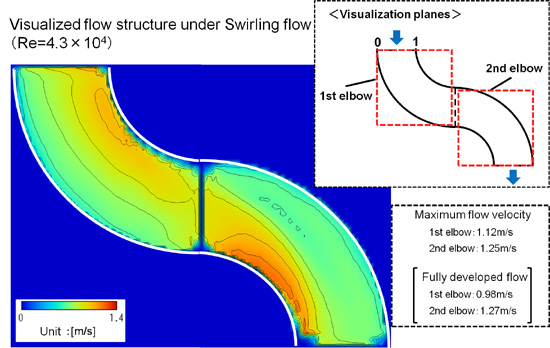

Swirling flow

In the case of swirling flow, a swriler is embedded at upstream of the entrance section. A Swirler is pipe, inside of which six blades are welded by 30-degree. When fluid flows in the swirler, fluid is rotating by these blades.

|

| Swirler |

|

| Experimental loop (Swirling flow) |

Visualized flow structure under Swirling flow

|

| Flow distribution at the inlet of dual elbow |

|

|

hashizume-stafflovehashizume@grp.tohoku.ac.jp

Copyright © Hashizume & Ito & Ebara & Cheng Lab., All Rights Reserved.