Efficiently cycling resources and CO2, for a cleaner environment!

Resource Circulation・Mineral Carbonation

Our study aims to establish a new system for resource circulation and CO2 recycling through the application of mineral carbonation technology.

CaO/MgO + CO2 → CaCO3/MgCO3

The reaction for mineral carbonation is presented above in its most simple form. This technology can produce stable carbonates by capturing CO2 from the atmosphere and other sources, leading to CO2 utilization and sequestration.

The raw materials for CaO/MgO in this technology are oxides, hydroxides, and hydrates of oxides. However, industrial wastes and byproducts can be applied as well, such as steel slag, waste concrete, coal ash, waste mine water, seawater (brine), concrete products, fresh concrete, and other industrial by-products.

Picture refers to “Izumi et al., J. Clean. Prod. 312, 127618, 2021.”

Characteristics of Mineral Carbonation

Mineral carbonation technology, in contrast to many other CCU (Carbon Dioxide Capture and Utilization) technologies, is fundamentally a spontaneous reaction with a negative Gibbs energy change of the reaction.

The minearl carbonation technology has these characteristics

- Spontaneous reaction (negative Gibbs energy of reaction)

- Does not require CO2-Free hydrogen

- High reaction selectivity with CO2

- Does not require high-purity or pressurized CO2

- A large market for carbonated products

- Reaction rates are very slow depending on the target rock or waste, so a reasonable approach to accelerate the reaction is needed.

Environment Remediation

We are developing a wide range of environmental remediation technologies.

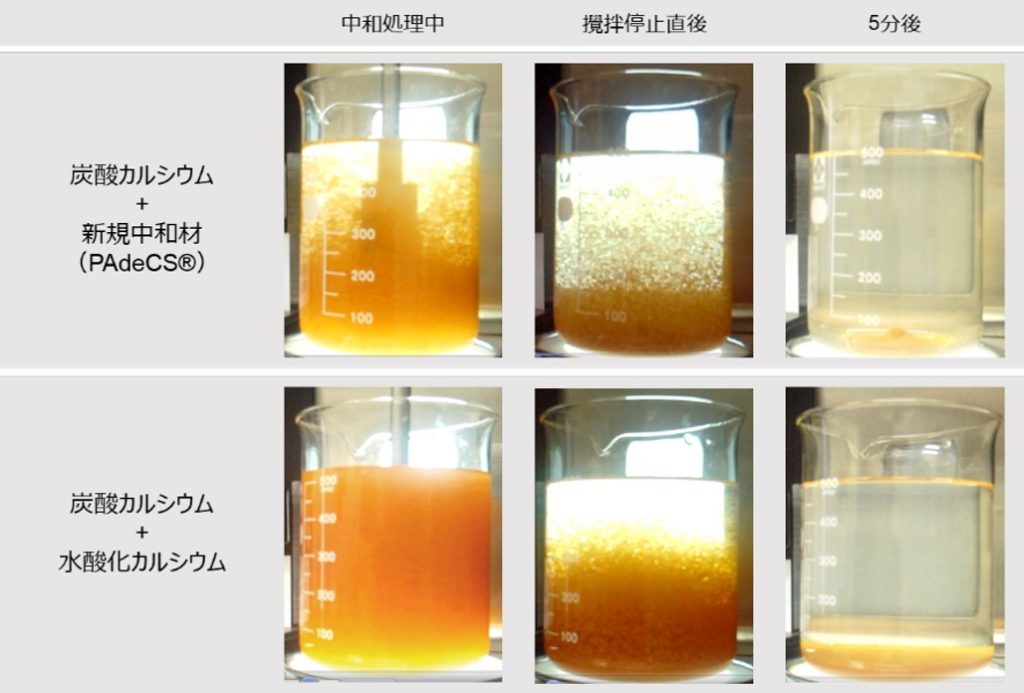

Novel and Recycled Materials

Novel and recycled materials for environmental purification are developed to achieve the goal of a sustainable environment.

For instance, in the left-hand side figure, the material derived from the cement and concrete recycling process was used as a novel neutralizer for environmental purification management of acid mine drainage. This material shows a competitive performance in removing toxic elements and a better performance in the sedimentation of residues compared with conventional chemicals.

Picture refers to “IIZUKA et al., Minerals Engineering, 2022, 188: 107819.”

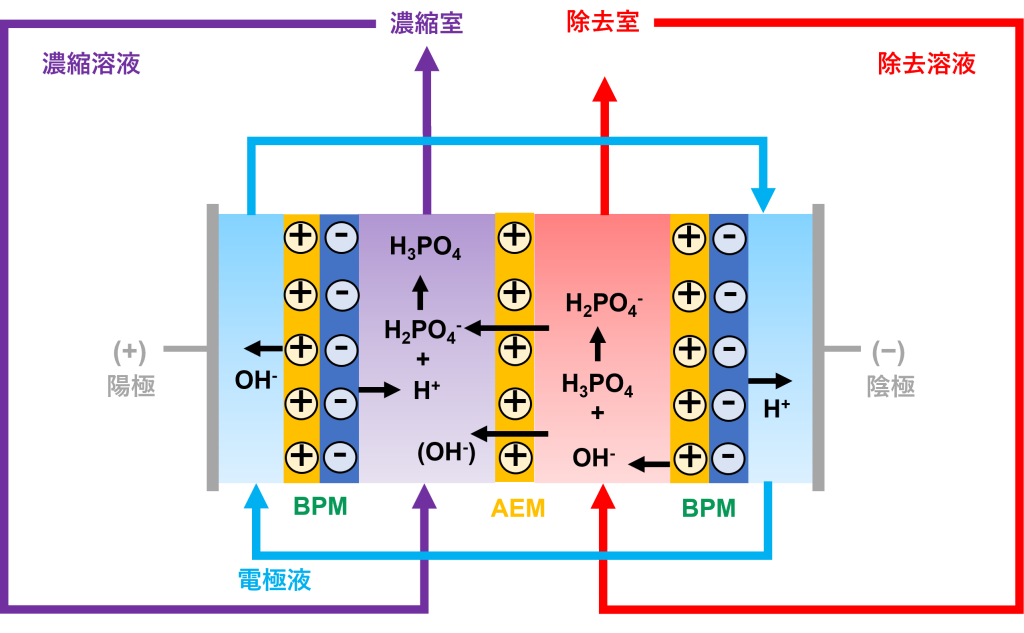

Electrochemical Technology

Electrochemical technology for wastewater treatment is developed.

For instance, in the left-hand side figure, bipolar membrane electrodialysis (BPED) is investigated to address phosphorus-enriched wastewater. By altering the pH of the solution without the addition of chemicals, phosphorus can be removed and concentrated in the solution by employing electric potential.

Besides, because of the unique characteristics of BPED, it can also be applied to recover acid and alkali chemicals from waste salt solutions which can be integrated with various issues.

Picture refers to “IIZUKA et al, ISIJ International, 2023, 63.7: 1172-1177.”

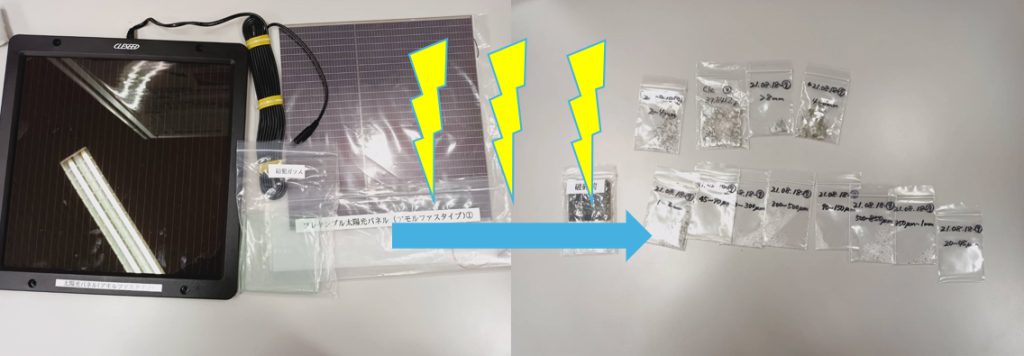

Liberation of composite materials (High-voltage pulse crushing)

Our group is also developing an effective liberation method to selectively crush the composite materials.

For instance, we are investigating the high-voltage pulse-crushing technique. In this technique. high-voltage pulses are applied several times to liberate and crush the composite materials in a simple way in a water environment. Many types of solar panels, including amorphous type are the subject of fundamental study.