【Presentation Points】

- Tohoku-TMIT (Tohoku Measuring Instrumentation Technologies) Corporation, a start-up company for contracted evaluation of magnetic and dielectric materials and consulting services, on January 4, 2023 (Headquarters: Sendai City, Miyagi Prefecture), was established.

- Available for measurement independent of sample size and shape compared to conventional methods

- Capable of evaluating ultra-thin films of 1 to 3 nm, and expected to be applicable to 12-inch wafers for integrated circuits

【Abstract】

In recent years, the rapid spread of 5th generation mobile communication systems (5G) and the Internet of Things (IoT) (1) has spurred the development of magnetic materials for magnetic sensors, power devices, magnetic memory, and radio wave absorbers. With such growing demand for magnetic and electromagnetic materials, material and device manufacturers recognize that their evaluation technologies are extremely important because the material properties of magnetic and dielectric materials directly affect the performance of their products. However, it has conventionally been difficult to evaluate the high-frequency characteristics of magnetic and electromagnetic materials in-line (2). In addition, special geometry, processing, etc. were required for evaluation, which presented challenges in terms of cost, time, labor, and versatility.

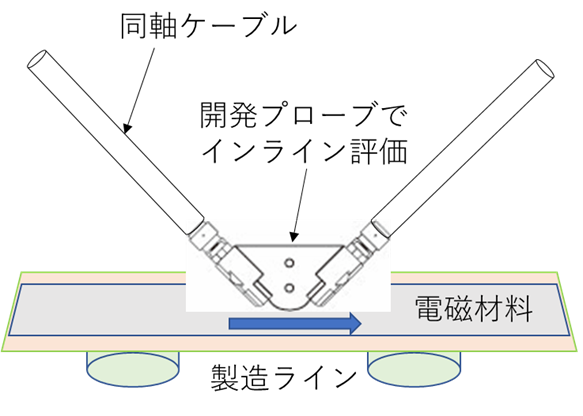

Professor Shin Yabukami and Academic Researcher Kazuhiko Okita of the Graduate School of Biomedical Engineering and Graduate School of Engineering at Tohoku University have established a start-up company, Tohoku-TMIT Corporation, which is engaged in commissioned evaluation of magnetic permeability and dielectric constant of electromagnetic materials and sales of probes using new technologies developed in the laboratory. Tohoku-TMIT Corporation was established on January 4, 2023. Tohoku-TMIT’s new technology enables in-line measurement, which has been difficult with conventional measurement technology, and is expected to reduce the time and effort required by customers for material characterization and enable more efficient evaluations (Figure 1).

【Reference information】

【Glossary】

Details(Text of Press Release)

1.Internet of Things (IoT): A system for collecting and analyzing data via the Internet from sensors embedded in everything, including automobiles, home appliances, industrial equipment, and infrastructure. Abbreviation for Internet of Things. It is used to provide better services and improve production efficiency at factories.

2.In-line: The flow process of producing a product. It is used in expressions such as “in-line inspection” to find defective products. Off-line inspection: A process in which parts are removed from the production line and inspected at a different location.

Contact information

(Regarding start-up companies)

Graduate School of Biomedical Engineering, Tohoku University

Graduate School of Engineering, Tohoku University

Professor Shin Yabukami

Academic Researcher Kazuhiko Okita

TEL: 022-795-7058 or 022-795-7059

E-mail: shin.yabukami.e7*tohoku.ac.jp (replace * with @)

kazuhiko.okita.b5*tohoku.ac.jp (replace * with @)

(Regarding the press coverage)

Graduate School of Biomedical Engineering, Tohoku University

TEL: 022-795-5826

E-mail: bme-pr*grp.tohoku.ac.jp (replace * with @)